CAPACITY

PRODUCTION FACILITY

Pulls Coffee boasts two modern factories in Long Hau Industrial Park, Long An Province. These facilities specialize in researching and producing roasted and ground coffee, as well as instant coffee, with a combined capacity of 1200 tons of roasted coffee and 400 containers of instant coffee annually.

Equipped with advanced production lines and strict quality control procedures, these factories ensure the full flavor and aroma of Vietnamese coffee beans reach every cup. Pull’s believes that no matter your location, you can enjoy “the taste of Vietnamese coffee” through their products.

Pull’s utilizes Hot Air roasting technology, not only saving fuel but also ensuring even roasting through controlled heat flow. Each 120kg capacity roaster is operated automatically under strict technician supervision using roasting batch management software. Technicians tailor parameters and roasting levels for each coffee type, guaranteeing roast consistency for every customer.

Furthermore, modern roasters store roasting information, techniques, and levels for each bean type, allowing Pull’s Coffee to personalize roasts for individual clients. This dedication to research and development (R&D) extends to their successful OEM/ODM partnerships, where Pull’s has earned praise for flexibility and professionalism.

Ultimately, Pull’s Coffee is committed to providing high-quality coffee products, made from carefully selected, pure coffee beans. They continuously diversify their product portfolio to cater to all consumer preferences, offering everything from rich roasted coffee to convenient instant options.

FARM AND THE JOURNEY FROM GREEN COFFEE BEANS TO FRAGRANT CUPS OF COFFEE

The purest coffee beans

Pull’s Coffee consistently has the highest quality raw materials available thanks to its partnerships with more than 16 coffee farms, spanning from Da Lat, Daklak, to Gia Lai. Green coffee beans from Pull’s Coffee are subject to stringent quality control measures during both the fertilization and procurement phases.

We collaborate closely with farmers to maintain the highest standards for the coffee – growing process, specifically, controlling the quality of output coffee, reducing production loss and increasing coffee quality uniformity.

The greatest effort process

These distinctively green coffee beans are full of potential aromas just waiting to be awoken by heat. Therefore, the roasting process strictly needs stability and guarantee to exaggerate the quality of the quintessential coffee beans. Processing and roasting coffee calls for extreme attentiveness, devotion, the use of modern technologies and scientific advancements. The path taken by green coffee beans to become a steaming hot cup of coffee is the evidence of the commitment and enthusiasm of coffee processors.

“From Farm to Cup”

Our products will be shipped to stores after leaving the production site, with standards regulated by a very stringent closed process. However, each variety of coffee is rigorously investigated in terms of brewing water temperature, proper amount of coffee, and brewing process, rather than merely being shipped by a deliveryman or prepared at random by the barista. We make sure that every drop of Pull’s Coffee must go through at least the whole process above before reaching the coffee lovers.

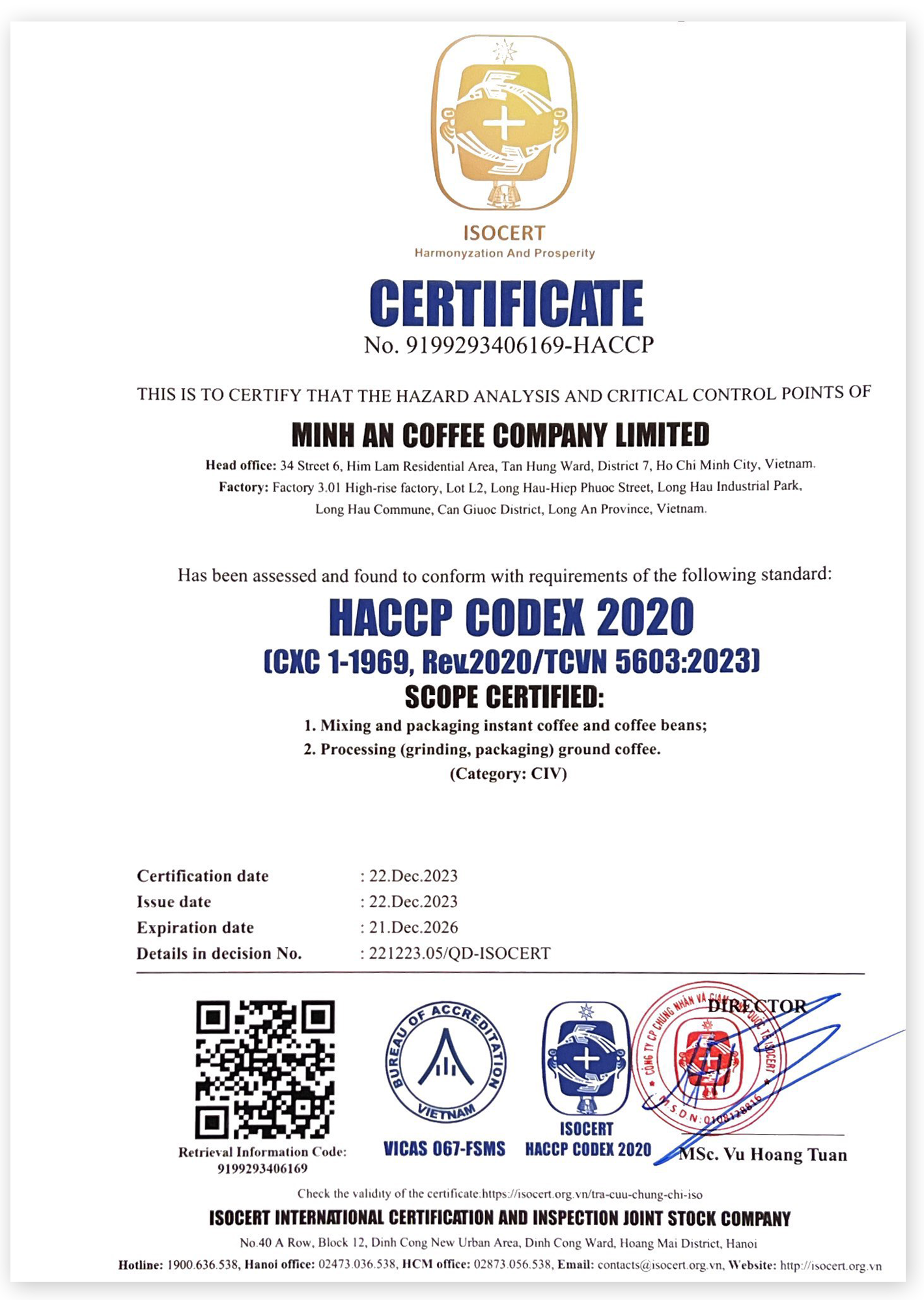

Commitment to International Quality: The Foundation for Pull's Coffee's Sustainable Development

We are dedicated to continuous research and development, creating innovative product lines and refining existing ones to achieve breakthroughs and gain recognition. Pull’s Coffee’s commitment to quality is evident in our certifications:

ISO 22000:2018 Standard Food Safety Management System

HACCP CODEX 2020 Global Food Safety Standards

FDA (Food and Drug Administration Certificate) Certification meeting FDA standards, allowing product importation into the US

Gold Prize at the “Coffees Roasted at the Origin” Competition: Organized by the AVPA in Paris 2022

CONTACT US

Learn More About Our Farms & Factory

EXPLORE OUR RANGE OF PRODUCTS

VIEW OUR PRODUCTS